Product Description

Specifications of fip plastic ppr ball valve:

| Handle—PP or ABS |

Ball— Stainless steel or brass |

seat Seal—PTFE, TPE |

| 0-Ring–EPDM,FPM,NBR |

Standard :BS, DIN , ANSI ,ASTM ,JIS ,GB |

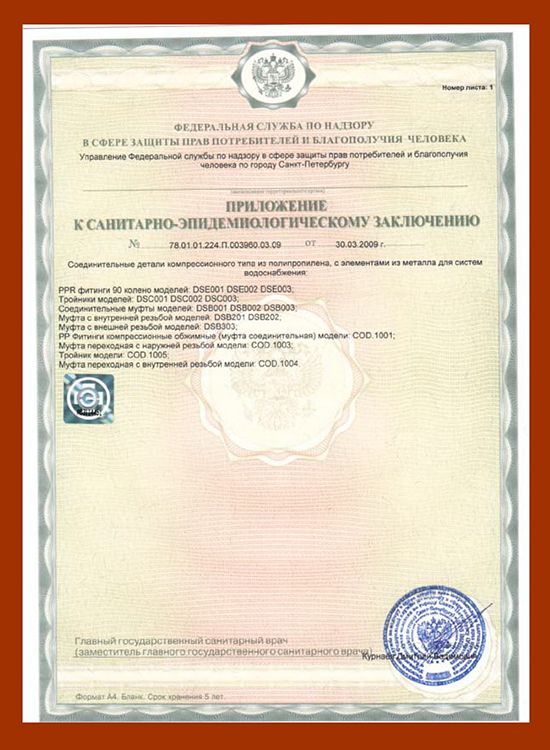

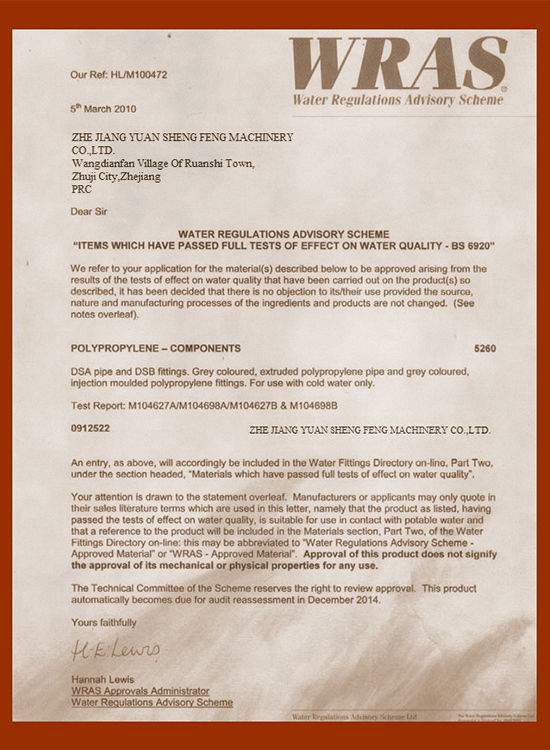

Certification: WARS , GB |

| Color: Grey, White or as per you requirements |

Branding :OEM / ODM |

Size: 20-110mm |

| Temperature of Media: Normal Temperature |

|

|

EHAO PPR Ball Valve exhibits excellent corrosion resistance properties and has the highest long-term hydrostatic strength of any other major thermoplastic material used for piping systems. Featuring lightweight, easy to install, maintenance-free, and will not rust, scale, pit or corrode. Choose EHAO valves for the most reliable, versatile and economical valve option in commercial and industrial applications.

Our Services

1. Any inquiries will be replied within 24 hours.

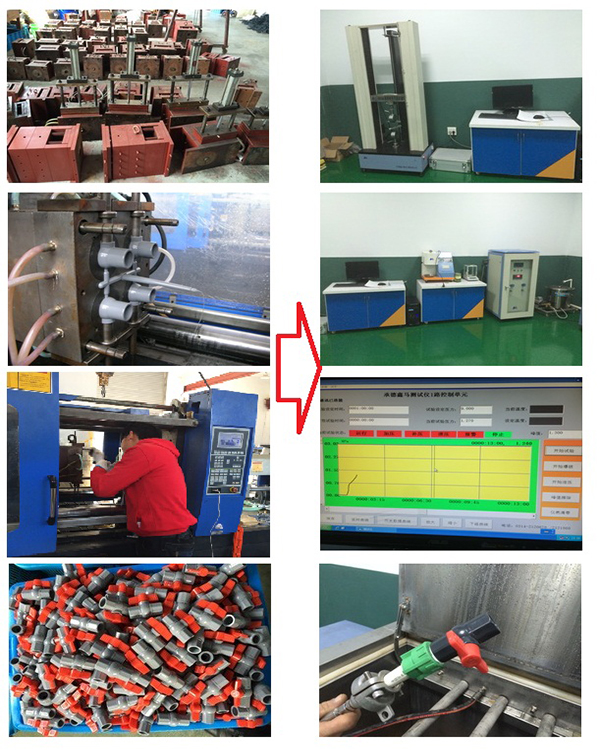

2. Professional manufacturer.

3. OEM is available.

4. High quality, standard designs,reasonable&competitive price,fast lead time.

5. Faster delivery: Sample will be prepared in 2-3days.

6. Shipping: We have strong cooperation with sea transportation land transportation air transport,ect.

7. You can also choose your own shipping forwarder,etc.

Sample for free,please give me inquiry !

FAQ

1. Why choose us ?

A. Genuine produces with excellent quality and competitive price.

B. Cooperating with the customers all over the world and knowing the markets very well.

C. After- Services will be highly-satisfied. Any problems and feedbacks will be answered in a short of time.

2. If we buy one 20ft container on time , any discount of price ?

Of course , we allways behind with our customer . We will earn more discount from us .

3. How about your guaranty ?

For PPR ,UPVC valves and fittings , granranty one year . For injection molds , granranty 300000 shots .

4. How to visit your factory ?

Our factory is near Hangzhou airport , Located in DianKou town . it will be taken 1 hour by bus . We will pick up you at airport.

Welcome to visit us !