21 Years Factory 3/4” Upvc tap for garden and bibcock for water supply manufacture, factory Factory for Tanzania

Short Description:

Product Detail

Product Tags

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for 21 Years Factory 3/4” Upvc tap for garden and bibcock for water supply manufacture, factory Factory for Tanzania, If you are interested in our products, please feel free to send us your inquiry. We sincerely hope to establish win-win business relationships with you.

| Standard or Nonstandard: Standard (BSPT , NPT) | Structure: Ball | Pressure: PN10 ,1.0mpa, 145psi |

| Power: Manual | Material: Plastic | Temperature of Media: Normal Temperature |

| Media: Water ,fuel , gas | Port Size: 3/4” | Place of Origin: Zhejiang, China (Mainland) |

| Model Number: EH04-3/4” | Brand Name: EHAO | Boday material: UPVC |

| Handle material: ABS, PP | ball material: PVC , PP | Sealing material: TPE , PFTE |

| Named : PVC water tap ,bibcock | carton size: 50*30*36 cm | pcs per ctn: 320 pcs /ctn |

| net weight: 61g | connect method: thread | color: white body , bule handle |

Packaging Delivery

| Packaging Details: | EXPORT CARTON , COLOR BOX WITH CUSTOMER REQUIRES. |

|---|---|

| Delivery Detail: | 20 DAYS |

Specifications

1. Size: 3/4″

2. All Standard:BSPT,ANSI,DIN,JIS ,NPT

3. Color:white,grey,blue

4. Virgin material

Specifications

plastic pvc bibcock

1)high quality and 0.5 million times lealess

2)light weight and beautiful appearance

1.DESCRPTION

1)material pvc

2)size: 3/4″

3)water pressure 1.0mpa

4)temperature resistence from – 5 deg to 60 deg

5)warranty have long service life

6)no fade,no canker,no aging

2.APPLICATIONS

1)Cold water supply facilities for public budings

2)Food,Chemical and Electronic industry pipeline networks,such as pipelines for transporting all kinds of corrosive liquids

3)Drinking water production system pipeline networks,such as pure water and mineral water pipes

4)Air conditioning facality pipelines and swimming pools

5) Compressed gas pipeline networks for industry use

3 .Packaging Shipping: polybag,color box,carton

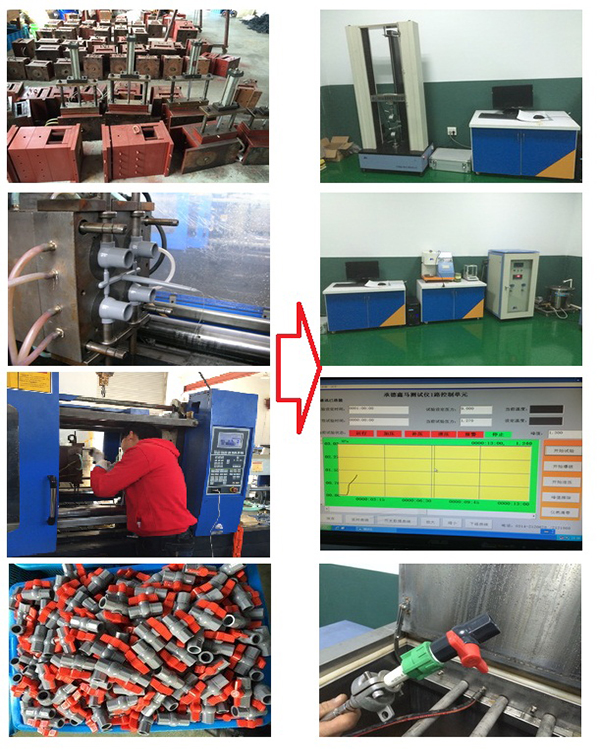

Pictures of pvc plastic water tap , for water supply 3/4” pvc bibcock :

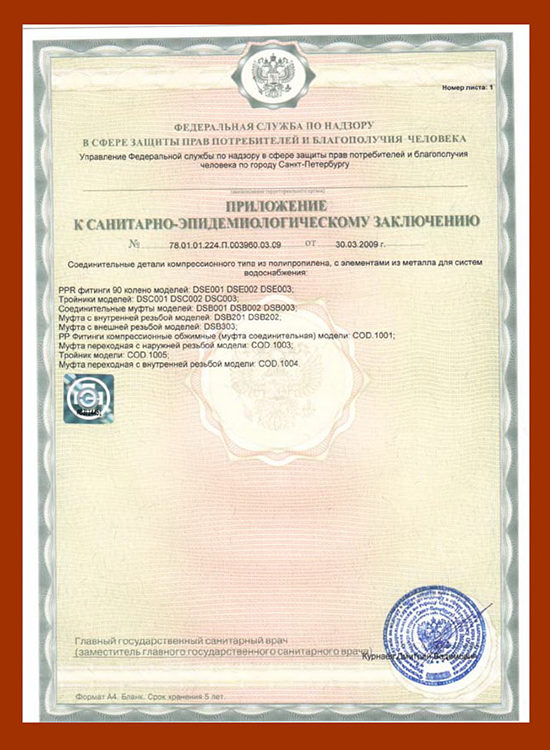

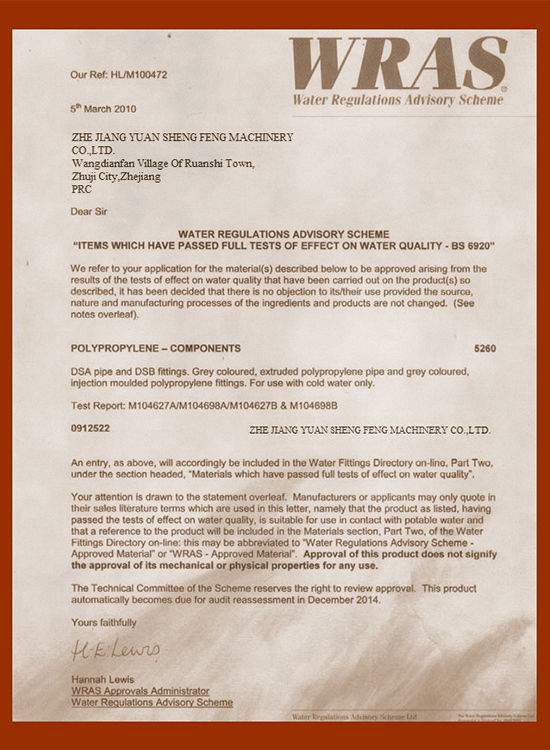

4 . Certification

5. Our customer

1.Any inquiries will be replied within 24 hours

2.Professional manufacturer.

3.OEM is available.

4.High quality, standard designs,reasonable&competitive price,fast lead time.

5.Faster delivery: Sample will be prepared in 2-3days.

6.Shipping: We have strong cooperation with sea transportation land transportation air transport,ect

7.You can also choose your own shipping forwarder. ,etc.

1.Why choose us?

A. Genuine produces with excellent quality and competitive price.

B. Cooperating with the customers all over the world and knowing the markets very well.

C. After- Services will be highly-satisfied. Any problems and feedbacks will be answered in a short of time.

2. If we buy one 20ft container on time , any discount of price ?

Of course , we allways behind with our customer . We will earn more discount from us .

3. How about your guaranty ?

For UPVC valves and fittings , granranty one year . For injection molds , granranty 300000 shots .

4. How to visit your factory ?

Our factory is near Hangzhou airport , Located in DianKou town . it will be taken 1 hour by bus . We will pick up you at airport.

Welcome to visit us !

3/4” Upvc tap for garden and bibcock for water supply with high quality

https://www.upvcballvalves.co.in/ KANAN PLAST : manufacturer of upvc ball valves, pvc ball valves, agriculture ball valves.

ENVOTEC MIDDLE EAST are experienced Valves Manufacturer and Supplier in Dubai UAE. We also specialize in providing high quality Control Valve Repair in Dubai.